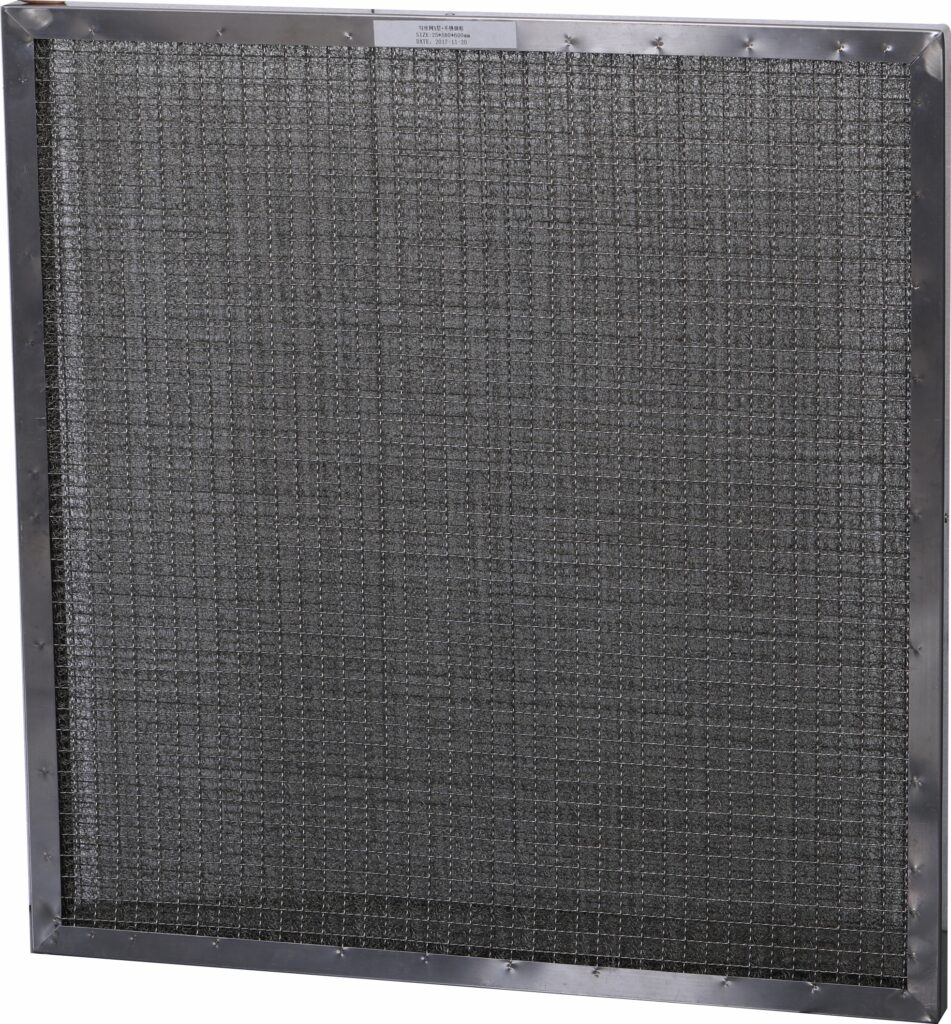

GT PANEL FILTER

Catagory : GAS TURBINE Filters

GT PANEL FILTER

HIGH DENSITY METALLIC HERRINGBONE MEDIA FILTER | GAS TURBINE FILTER

Power machinery Air Intake filters for coarse filtration with High density metallic Fiber media and tackified media for particle trapping.

| PRODUCT SPECIFICATIONS | ||

|---|---|---|

| Filter Category | Woven Metallic Herringbone Demister Pre-Filter | |

| Efficiency (ISO 16890) | ISO COARSE 30% | |

| Filter Class (EN 779: 2012) | G2 | |

| Filter Class (ASHRAE 52.2: 2017) | MERV 4 | |

| Filter Depth | 2” & 4” | |

| Filter Media | Woven Metallic wire (Stainless Steel / Aluminum) | |

| Filter Frame | Stainless Steel / Aluminum/ Galvanized Steel | |

| Media Support | Metallic Wire Mesh support on both sides | |

| Recommended Final Pressure Drop | 1.5” wg | |

| Recommended Face Velocity | 2.5 m/sec-3 m/sec | |

| Maximum Temperature | 200°C | |

| Maximum Relative humidity | 100% | |

| Fire Resistance | UL 900 listed | |

APPLICATIONS

- Gas Turbine Intake

- On Shore and Off shore

- Coastal and Marine Areas

- Kitchen Extract

- Industrial Plants

- Engine Rooms

- Refrigeration Plants

- Compressor Plants

- Air Handling Units

Features & Advantages

- The GT Panel Filter is metallic woven media (Stainless steel / Aluminum) with tackifier for usage in harsh and Aggressive Environmental conditions.

- It has Continuously woven media which is adhesive coated and can be used for filtering out Coarse dust particles as well as used for moisture separation.

- The filter has drain holes at the bottom side of frame for allowing separated moisture and mist to flow away from inside the filter.

- The filter frame is made of metallic frame with options of Stainless Steel, Aluminum, Galvanized steel

- The media has metal mesh support on both sides which holds the media intact and supports the media.

- The complete construction of the filter components in Stainless Steel or Aluminum makes it rust free and robust.

- When the filter reaches its final replacement pressure drop, the filter can be taken out washed and cleaned.

- The filter is available in Grades G2 as per EN 779 & MERV 4 as per ASHRAE 52.2 test standards.

- The filter is UL 900 listed for fire rating.

- These filters are used for Coarse Filtration and moisture separation applications where the environmental condition is highly humid, oil mist filled, foggy or misty and contains high amounts of dust particles.

- They are preferred filters for air Intake applications for Gas turbines, Industrial Plants, Marine and Coastal area AHUs, On shore and Off shore buildings, Engine Rooms, Compressor plants.

- These Pre-Filters protect the Gas turbine from air borne and moisture-based contaminants that cause erosion, corrosion and fouling of the turbine blades. This improves the performance of the turbine blade thus reducing the turbine repair and turbine down time.

- This works like a combination filter for Coarse particulate matter and water mist separator.

- The media is thermally stable up to 200 Deg C

- The media has High dust holding capacity combined with lower pressure drops.

- These filters can be installed in new or existing systems and arranged either in filter banks or in filter housings.

- These filters can be manufactured in a range of standard sizes.